Detailed Product Description

| Working Temperature:: | -25℃– +55℃ | Working Humidity:: | 20%–90%RH, No Drips Concreted |

|---|---|---|---|

| Degree Of Protection:: | IP54 | Install Position:: | Wall Mounting |

| Shipping Carton Dimension:: | 34*36*53cm | Unit Dimension (L X W X H):: | 170*155*85mm |

1.Specifications:

| Model | MP-S1 plus |

| Description | Single Pump Control Panel |

| Input Voltage | AC220-240V,Single Phase,50HZ/60HZ,DOL |

| Output Power | 0.37-2.2KW(0.5-3HP) |

| Capacitor | Reserved space for installing start capacitor |

| Degree of protection | IP54 |

| Protection Function | Over load protection |

| Over/Under voltage protection | |

| Pump stalled protection | |

| Dry run protection with sensor free | |

| Other features | Memory function when power off & recovery |

| LCD screen displaying motor running stats | |

| Push button calibration | |

| Main installation data | Working temperature:-25ºC– +55ºC |

| Working humidity:20%–90%RH, no drips concreted | |

| Install position:Wall mounting | |

| Unit dimension(L*W*H) | 170*155*85mm |

2.Description:

Single Phase Pump Control Panel (MP-S1 plus) Parameter Calibration With CE Certification

MP-S1 plus,it’s an Single Pump Control Panel.If don’t connect the level probe,it’s same as an motor protector/Starter.It has More control functions,but motor protector just start & protect pump.

3.Applications:

Contorl and protect universal pump

Using liquid probe sensor or float switch or pressure switch to control pump start and stop.

Applied for water supply by liquid level control through float switch or liquid probe.

Applied for water supply by pressure control through pressure switch and pressure tank.

Applied for drainage by liquid level control through float switch or liquid probe.

&

4.Feature Advantage:

Leading Intelligent Pump Controller features: Parameter Calibration by single button pressing

1.what is Parameter Calibration?

pump manufacturer, pump users etc all know that during the practical operation, there are two major pump running parameters: voltage & ampere, Leading intelligent pump controller can memorize these two major running parameters during the pump operation and protect the pump reliably according to these two major parameters;

Traditional pump controller can not memorize pump running parameters, so it can not protect the pump reliably.

2.how to do Parameter Calibration? ( two easy simple steps)

Step 1: once the pump and Leading pump controller installation completed, run the pump under manual state, check the whole pump system work normal including the voltage, ampere and pump running state

Step 2: press STORE button, Leading pump controller will memorize all the running parameters of pump and protect the pump according the memorized running parameters

3.The purpose of Parameter Calibration

The main purpose of Parameter Calibration is to give more reliable protection against pump and motor, additionally, all the running parameters can be adjusted according to the pump supplier/users special technical request, so it can give the pump supplier/user more customized application

4.Basic Parameter Calibration item list

| Item | Parameter Calibration |

| 1) | Dry Run protection trip response time |

| 2) | Dry Run protection recovery time |

| 3) | Dry Run protection trip ampere |

| 4) | Over Load protection trip ampere |

| 5) | Pump Stalled protection trip ampere |

| 6) | Under Voltage protection trip voltage |

| 7) | Over Voltage protection trip voltage |

Because Leading pump controller adopts microchip processing technology, we can add parameter item according to pump supplier/user customized technical request

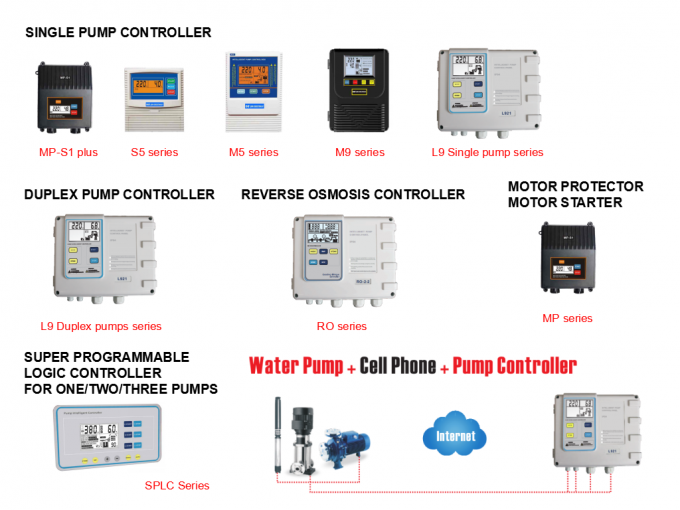

5.Other Products and pictures:

5.FAQ

Can i have some samples ?

Yes ,we can send you samples for testing,contact us for details

What’s delivery time ?

For standard pump control panel ,it usually takes about 7 working days;

For non-standard,it usually takes 15-20days ,please contact us for details;

Can I do OEM or ODM ?

Yes,we have our own engineering team and we do accept OEM and ODM,but there is ordering quantity requirement;

How does your factory do the quality control ?

Our production process follow up the ISO standard and we control the product quality from the raw materials to the finished product,each of our control panel will be fully assembled and strictly tested before packing and shipping ;

What is the approximate life time for your control panel ?

The designed life time of control panel is 8 years ;

What is your after sales service policy ?

According to the ordering quantity,we will give some free spare parts or controller for maintenance or replacement and we will give technical training;

How can i trust you ?

We have being developing the pump control panel manufacturing and selling for 15 years ,now many pump supplier from China and overseas are using our controller to control and protect their pump and motor.

Where is your location and transportation guide?

From Guangzhou to Changsha takes 1hour by air, 2.5hour by high speed train

From Shanghai to Changsha takes 1.5hour by air, 5hour by high speed train

From Beijing to Changsha takes 2.5hour by air

From Hong Kong to Changsha takes 2hour by air